ISES Corporation recently conducted an analysis of the impact of legacy building control systems, particularly pneumatic HVAC systems, on building system operations and on building users’ perception of maintenance staff. The following is a brief synopsis of those findings.

Pneumatic control systems dominated the commercial controls industry for most of the 20th century. They were inexpensive and easy to set up. However, these systems have inherent design and operational problems:

- Proportional control offset

- Longer system response times

- Challenging maintenance

Enter technology development to improve system operation. Direct Digital Control (DDC) was developed in Australia around 1982. DDC systems replaced older pneumatic control systems that were inefficient and impossible to keep calibrated. Most facilities built in the US since the mid-1980s are equipped with some form of DDC.

Despite the overwhelming advantages of DDC systems, many university and office campuses are deferring replacement of antiquated pneumatic systems. These deferral decisions are primarily a result of insufficient capital funds. Facilities managers can help themselves by identifying the costs directly impacted by the continued use of these aging control systems.

They include:

- Lack of energy efficiency resulting in higher operating expenses

- Increasing costs each year of maintaining old pneumatic systems

- Increasing costs each year for emergency callouts due to failing system equipment

- Discomfort of building occupants (due to imprecise setpoints)

- Difficulty locating discontinued replacement components

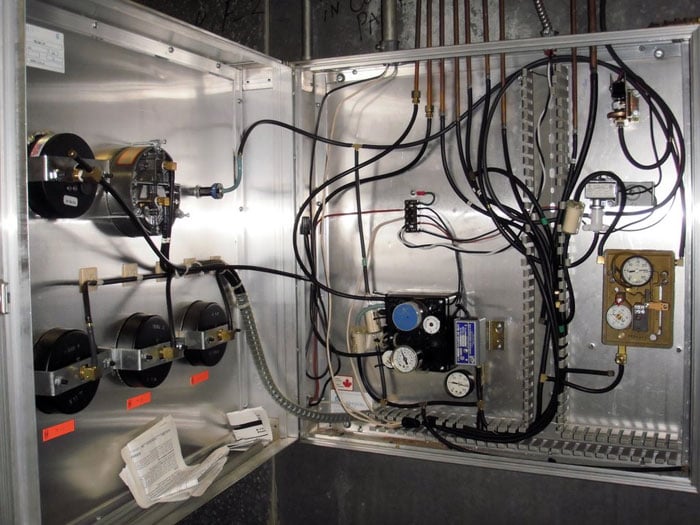

Pneumatic systems are subject to controller contamination from air compressors that pass lube oil into the air distribution piping. Faulty compressed air dryers cause moisture to enter the control devices. Pneumatic systems are also more challenging when diagnosing problem operation, since there is no accurate reflection of actuator position to aid the diagnosis. These problems with the older systems cause an increase in customer complaints often borne by facilities maintenance group personnel, who are powerless to alter system dynamics.

The most critical drawbacks with the use of pneumatic final control elements, such as airflow dampers and valve actuators, are:

- Lack of remote monitoring inherent in pneumatic controls

- Cost in labor and time delays in service that result from having to physically visit these pneumatically controlled spaces in response to complaints

- Lack of trends, making diagnosis and repair of intermittent issues and low-grade inefficiencies extremely difficult.

The continued presence of pneumatic controls for campus HVAC systems is a common problem among institutions across the country, as replacement of these older systems requires expensive capital investment in an arena of competing needs and finite resources.

Replacement of pneumatic control devices is often a deferred maintenance issue, as components remain operational beyond expected useful and reliable operating life. These component/system replacements are also classified as capital renewal projects and these projects are usually expensive.